Nigeria’s beverage industry is massive, with the country ranking as Africa’s largest beer consumer and producer. Behind the bottles that package these drinks is Beta Glass, a company responsible for manufacturing 70% of the glass containers used in Nigeria.

Established in 1974, Beta Glass has built a reputation for quality and precision, operating two advanced plants in Agbara, Ogun State, and Ughelli, Delta State. Producing over 2 million bottles daily and more than 650 million annually, the company has remained a leader in the industry through consistent technological advancements.

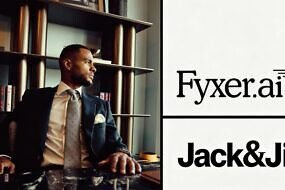

Jagdish Agarwal, Beta Glass COO Photo Credit:Technext

Jagdish Agarwal, Beta Glass COO Photo Credit:Technext

Jagdish Agarwal, Chief Operating Officer of Beta Glass, revealed that the company’s capacity is fueled by continuous expansion and an annual investment of €4 million in automation upgrades. A recent improvement to the GF1 furnace, completed in just 32 days, has increased production by 30 tons per day and extended the furnace’s lifespan by up to a decade.

Beta Glass employs a fully automated nine-step production process: raw material sourcing, batching, melting, feeding, forming, annealing, cold-end treatment, inspection, and packaging. According to Agarwal, this advanced system linked directly to European Original Equipment Manufacturers (OEMs) ensures consistency and high-quality output.

The entire process, from raw material to finished product, takes approximately 38 hours. The primary ingredients include silica sand, limestone, soda ash, and cullet (recycled glass), with 50% of materials coming from recycled sources. While many raw materials are sourced locally from states like Ogun, Oyo, and Kaduna, some, such as soda ash and sodium sulfate, are imported from China, Romania, Turkey, and Germany.

Beta Glass Executives: L-R: Jagdish Agarwal, Chief Operations Officer, Beta Glass Plc; Sharin Sweet, Head of Sales, Beta Glass Plc; Alexander Gendis, Chief Executive Officer, Beta Glass Plc; Helene Paradisi, Chief Financial Officer, Beta Glass Plc; Govind Prasad, Guinea Plant Manager, Beta Glass Plc; Gladys Umoh, HR Director, Beta Glass Plc.

Beta Glass Executives: L-R: Jagdish Agarwal, Chief Operations Officer, Beta Glass Plc; Sharin Sweet, Head of Sales, Beta Glass Plc; Alexander Gendis, Chief Executive Officer, Beta Glass Plc; Helene Paradisi, Chief Financial Officer, Beta Glass Plc; Govind Prasad, Guinea Plant Manager, Beta Glass Plc; Gladys Umoh, HR Director, Beta Glass Plc.

Automation has also improved workplace safety. The company’s safety records indicate nearly five years without a major accident, with the latest report showing 1,650 days of incident-free operations. A digital monitoring system detects potential hazards, ensuring a safe environment for employees.

Despite challenges posed by foreign exchange fluctuations, Beta Glass continues to thrive by increasing local sourcing and adjusting pricing strategies. CEO Alexander Gendis emphasised the company’s commitment to growth in Nigeria, describing the country as a vibrant place filled with opportunity.

No Comments